Technical advantages of excavator high frequency screening bucket

In the world of construction and excavation, efficiency and precision are paramount. The excavator high frequency screening bucket has emerged as a game-changing tool, revolutionizing the way materials are sorted and processed on job sites. This innovative attachment combines the power of an excavator with advanced screening technology, offering a range of benefits that enhance productivity and streamline operations.

Efficient Production: Maximizing Output with Cutting-Edge Technology

The excavator high frequency screening bucket stands out for its remarkable efficiency in material processing. Unlike traditional screening methods, this advanced attachment utilizes high-frequency vibration to separate materials quickly and effectively. The heart of this efficiency lies in its sophisticated vibration mechanism, which typically operates at frequencies exceeding 24 Hz with amplitudes ranging from 1.0 to 2.5 mm. This high-speed, low-amplitude motion is ideal for screening fine materials, ensuring thorough separation without damaging the screened content.

One of the key factors contributing to the bucket's efficient production is its hydraulic motor-driven system. This powerful motor generates the high-speed shaking motion that is crucial for effective screening. The combination of high frequency and optimal amplitude creates a perfect balance, allowing materials to be processed rapidly while maintaining high-quality output. This system significantly outperforms standard grid buckets, offering a substantial increase in production efficiency.

Its design also plays a crucial role in its efficiency. The bucket is engineered to maximize material flow, with strategically placed baffles and screens that guide materials through the screening process smoothly. This design minimizes clogging and ensures consistent performance, even when dealing with challenging or varied materials. The result is a continuous, high-volume screening process that can significantly reduce the time and labor required for material sorting on construction sites.

Moreover, the versatility of the excavator high frequency screening bucket adds to its efficiency. It can handle a wide range of materials, from fine sand to larger aggregates, making it an invaluable tool for diverse applications. Whether it's separating topsoil, screening demolition waste, or processing quarry materials, this attachment adapts to various tasks without the need for multiple specialized equipment. This versatility not only enhances productivity but also contributes to cost savings and simplified logistics on job sites.

Replaceable Screen: Adaptability for Diverse Applications

One of the most significant advantages of the excavator high frequency screening bucket is its replaceable screen system. This feature dramatically enhances the attachment's versatility and longevity, allowing it to adapt to a wide range of screening requirements with minimal downtime. The ability to interchange screens with varying apertures means that a single bucket can be quickly modified to handle different material sizes and types, catering to diverse project needs.

The replaceable screen system typically consists of a series of interchangeable mesh panels or perforated plates. These screens are designed for easy removal and installation, often utilizing a simple yet secure locking mechanism. This design allows operators to switch between different screen sizes quickly, adapting to changing material specifications or project requirements without the need for specialized tools or extensive downtime.

The range of available screen sizes is extensive, typically spanning from fine mesh for sand and small particles to larger openings for coarser aggregates. This variety ensures that the excavator high frequency screening bucket can be optimized for specific tasks, whether it's separating fine soil particles, screening medium-sized gravel, or sorting larger rocks and debris. The ability to fine-tune the screening process by selecting the appropriate mesh size leads to improved material quality and reduced waste, ultimately enhancing the overall efficiency of the operation.

Furthermore, the replaceable screen feature contributes significantly to the maintenance and longevity of the equipment. Screens are subject to wear and tear, especially when processing abrasive materials. With a replaceable system, worn screens can be easily swapped out for new ones, extending the life of the bucket and maintaining optimal performance. This feature not only reduces maintenance costs but also minimizes downtime, ensuring that the excavator high frequency screening bucket remains a reliable and productive tool throughout its lifespan.

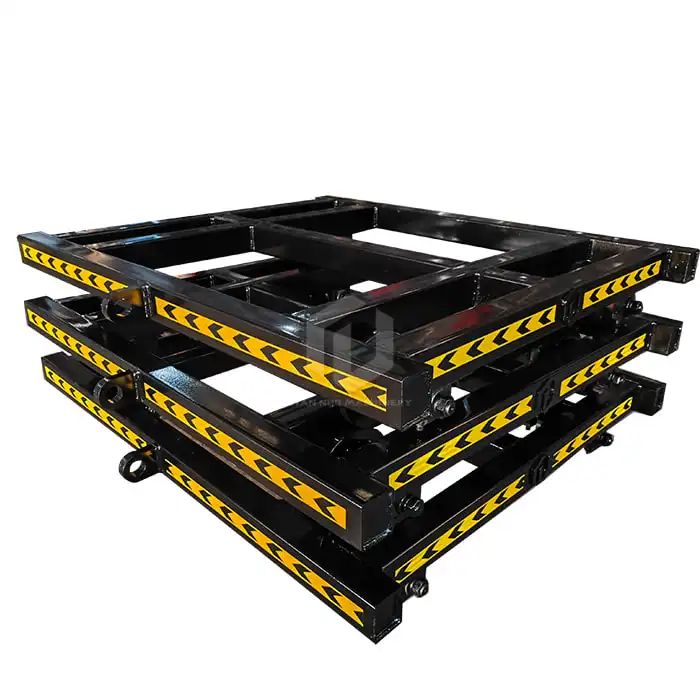

High-Strength Structure: Durability Meets Performance

The excavator high frequency screening bucket is built to withstand the rigors of heavy-duty construction and excavation work. Its high-strength structure is a critical feature that ensures durability, reliability, and consistent performance in challenging environments. The construction of this attachment is a testament to engineering excellence, combining robust materials with innovative design to create a tool that can handle the most demanding screening tasks.

At the core of the bucket's structural integrity are high-performance steel plates. These plates are carefully selected for their exceptional strength-to-weight ratio, providing the necessary durability without adding excessive weight to the excavator. The use of high-grade steel ensures that the bucket can withstand the intense vibrations and stresses associated with high-frequency screening operations, as well as resist wear from abrasive materials.

The assembly of the excavator high frequency screening bucket employs advanced welding techniques, including the use of mortise and tenon joints. This traditional woodworking technique, adapted for metal fabrication, creates incredibly strong connections between components. The mortise and tenon method distributes stress more evenly across the joints, reducing the risk of structural failure and enhancing the overall rigidity of the bucket. This robust construction ensures that the bucket maintains its shape and performance even under heavy loads and continuous operation.

Another critical aspect of the bucket's high-strength structure is the integration of maintenance-free shafts and bearings. These components are engineered to withstand the high-frequency vibrations and heavy loads associated with screening operations. By using high-strength materials and advanced sealing technologies, these shafts and bearings offer extended service life and reduced maintenance requirements. This design feature not only contributes to the overall durability of the bucket but also minimizes downtime and maintenance costs, enhancing the equipment's long-term value.

The structural design of the excavator high frequency screening bucket also incorporates features to optimize material flow and reduce wear. Strategically placed wear plates protect high-impact areas, while the bucket's contours are engineered to facilitate smooth material movement. This thoughtful design not only enhances screening efficiency but also contributes to the longevity of the attachment by minimizing stress on critical components.

Excavator High Frequency Screening Bucket For Sale

The high-frequency screening bucket represents a significant advancement in material processing technology for construction and excavation projects. Its efficient production capabilities, facilitated by high-frequency vibration and hydraulic power, set new standards for screening productivity. The replaceable screen system offers unparalleled versatility, allowing operators to adapt quickly to diverse material requirements. Meanwhile, the high-strength structure ensures that this attachment can withstand the demands of heavy-duty use, providing long-term reliability and performance.

For those in the construction, quarrying, or landscaping industries seeking to enhance their material processing capabilities, the excavator high-frequency screening bucket offers a compelling solution. Its ability to rapidly remove impurities from ballast stone through cross-line rubbing and tooth vibration, combined with its high production efficiency compared to standard grid buckets, makes it an invaluable tool for a wide range of applications.

If you're considering investing in an excavator high frequency screening bucket, it's crucial to choose a reputable manufacturer that can provide high-quality, reliable equipment. Shandong Tiannuo Engineering Machinery Co., Ltd. stands out as a leading provider in this field, offering innovative solutions backed by extensive research and development.

To learn more about our high frequency screening buckets and how they can benefit your operations, we invite you to reach out to our expert team. Our manager is available at arm@stnd-machinery.com, and our team members can be contacted at rich@stnd-machinery.com and tn@stnd-machinery.com. We're here to provide you with detailed information, answer your questions, and help you find the perfect screening solution for your specific needs.

Embrace the future of material screening technology and take your project efficiency to new heights with an excavator high-frequency screening bucket from Shandong Tiannuo Engineering Machinery Co., Ltd. Contact us today to explore how our cutting-edge equipment can transform your operations and drive your success.

References

- Shandong Tiannuo Engineering Machinery Co., Ltd. Official Website

- Construction Equipment Magazine: "Advancements in Screening Technology"

- Journal of Construction Engineering: "Efficiency Analysis of High-Frequency Screening in Construction Applications"

- Materials Processing Technology Handbook, 5th Edition

- International Conference on Construction and Building Materials: Proceedings 2023

_1733877348138.jpg)