How to choose an excavator grab arm based on excavator tonnage?

Selecting the right excavator grab arm is crucial for maximizing efficiency and productivity in various construction and material handling applications. The choice of grab arm depends significantly on the excavator's tonnage, as well as the specific requirements of the job at hand.

Relationship Between Excavator Tonnage and Grab Arm Selection

Excavator tonnage is a critical factor in determining the appropriate grab arm for your machine. The tonnage of an excavator refers to its operating weight, which directly influences its lifting capacity and overall performance. When selecting a grab arm, it's essential to consider the excavator's tonnage to ensure compatibility and optimal functionality.

Typically, excavators are categorized into different weight classes, ranging from mini excavators (less than 6 tons) to large excavators (over 40 tons). Each class is suited for specific types of grab arms, designed to handle different materials and workloads. For instance, a 12-16 ton excavator might be ideal for light to medium-duty applications, while a 40-49 ton machine would be more suitable for heavy-duty tasks in industries such as mining or large-scale construction.

The relationship between excavator tonnage and grab arm selection is not just about matching weight capacities. It also involves considering factors such as the arm's reach, the types of materials to be handled, and the specific job requirements. A larger excavator with a higher tonnage will generally be able to accommodate a more substantial grab arm, allowing for increased lifting capacity and reach. Conversely, a smaller excavator will require a lighter, more compact grab arm to maintain balance and prevent overloading.

When choosing a grab arm based on excavator tonnage, it's crucial to consult the manufacturer's specifications and recommendations. These guidelines typically provide detailed information on the compatible grab arm sizes and types for each excavator model. Additionally, factors such as the excavator's hydraulic system capacity and boom configuration should be taken into account to ensure seamless integration and operation of the grab arm.

Grab Arm Types Suitable for Different Excavator Sizes

Excavator grab arms come in various types, each designed to cater to specific applications and excavator sizes. Understanding the different grab arm types and their suitability for various excavator tonnages is essential for making an informed decision. Let's explore some common grab arm types and their ideal excavator size ranges:

1. Light-Duty Grab Arms: These are typically suitable for excavators in the 12-16 ton range. They are designed for handling lighter materials such as wood, light scrap, and small debris. Light-duty grab arms offer good maneuverability and are ideal for applications that require precision rather than brute force.

2. Medium-Duty Grab Arms: Excavators in the 20-27 ton category often utilize medium-duty grab arms. These are versatile attachments capable of handling a wide range of materials, including mixed waste, construction debris, and medium-sized scrap metals. They offer a good balance between lifting capacity and agility.

3. Heavy-Duty Grab Arms: For excavators in the 30-38 ton range, heavy-duty grab arms are the preferred choice. These robust attachments are designed to handle substantial loads, making them ideal for applications such as dock unloading, railway transportation unloading, and handling large scrap metals.

4. Extra Heavy-Duty Grab Arms: Excavators in the 40-49 ton category and above typically use extra heavy-duty grab arms. These are engineered for the most demanding applications, such as mining operations, large-scale demolition projects, and handling extremely heavy materials. They offer maximum strength and durability to withstand intense use in challenging environments.

5. Specialized Grab Arms: Some grab arms are designed for specific applications, regardless of excavator size. For example, there are grab arms specifically engineered for handling logs, sorting recyclables, or manipulating odd-shaped objects. These specialized attachments may be available for various excavator tonnages, with their design focused more on the task at hand rather than the machine's size.

When selecting a grab arm type, it's essential to consider not only the excavator's tonnage but also the nature of the work to be performed. A medium-duty excavator might benefit from a heavy-duty grab arm if the job requires handling particularly dense or heavy materials. Conversely, a larger excavator might use a lighter grab arm for tasks that demand precision over raw power.

It's worth noting that advancements in materials and design have led to the development of grab arms that can be used across a range of excavator sizes. These versatile attachments often feature adjustable settings or modular components that allow them to be adapted for different machine sizes and applications. However, it's crucial to ensure that any adjustable grab arm is properly configured for your specific excavator to maintain safe and efficient operation.

Balancing Strength and Flexibility in Grab Arm Selection

When choosing an excavator grab arm, finding the right balance between strength and flexibility is crucial for optimal performance. This balance is particularly important when considering the relationship between the grab arm and the excavator's tonnage. A grab arm that is too strong for the excavator may overburden the machine, leading to reduced efficiency and potential damage. Conversely, a grab arm that lacks sufficient strength may not be able to handle the required workload, resulting in decreased productivity.

To achieve the ideal balance, consider the following factors:

1. Material Strength: The materials used in the construction of the grab arm play a significant role in its overall performance. High-strength steels and alloys can provide the necessary durability for heavy-duty applications while keeping the weight of the attachment manageable. When selecting a grab arm, inquire about the materials used and their properties to ensure they align with your excavator's capabilities and job requirements.

2. Design Efficiency: Modern grab arms often incorporate innovative design features that enhance both strength and flexibility. For example, some models use a honeycomb structure or reinforced stress points to increase strength without adding excessive weight. Look for grab arms that utilize intelligent design principles to maximize performance while maintaining compatibility with your excavator's tonnage.

3. Hydraulic System Compatibility: The grab arm's hydraulic system should be well-matched to your excavator's capabilities. A hydraulic system that is too powerful for the excavator may cause control issues, while an underpowered system may result in slow or inefficient operation. Ensure that the grab arm's hydraulic requirements are within the excavator's specifications for optimal performance.

4. Weight Distribution: The way weight is distributed across the grab arm can significantly impact its performance and the excavator's stability. A well-designed grab arm should distribute weight evenly, allowing for smooth operation and reducing strain on the excavator's boom and arm. This is particularly important for larger excavators, where the grab arm's weight can have a more pronounced effect on the machine's balance.

5. Adjustability and Versatility: Some grab arms offer adjustable features that allow for greater flexibility across different applications. These may include interchangeable teeth or tines, adjustable opening widths, or rotational capabilities. While these features can enhance the grab arm's versatility, it's important to ensure that they don't compromise the overall strength and durability required for your specific tonnage and application.

6. Maintenance and Durability: Consider the long-term durability and maintenance requirements of the grab arm. A balance between strength and flexibility should also extend to the arm's ability to withstand wear and tear over time. Look for grab arms with robust construction and easily replaceable wear parts to ensure longevity and minimize downtime.

7. Safety Features: The integration of safety features is crucial when balancing strength and flexibility. Look for grab arms that incorporate safety mechanisms such as load-holding valves, which prevent sudden drops in case of hydraulic failure. These features should be designed to work seamlessly with the excavator's existing safety systems.

8. Customization Options: Some manufacturers offer customization options that allow you to tailor the grab arm to your specific needs while maintaining compatibility with your excavator's tonnage. This can be particularly beneficial when standard off-the-shelf solutions don't quite meet your requirements.

By carefully considering these factors and working closely with reputable manufacturers or suppliers, you can select a grab arm that offers the ideal balance of strength and flexibility for your excavator's tonnage and intended applications. Remember that the goal is to enhance your excavator's capabilities without compromising its performance or safety.

Tiannuo Machinery Excavator Grab Arm Quotation

Selecting the right grab arm is a critical decision that can significantly impact your project's efficiency and success. By considering factors such as excavator tonnage, grab arm types, and the balance between strength and flexibility, you can make an informed choice that enhances your operations.

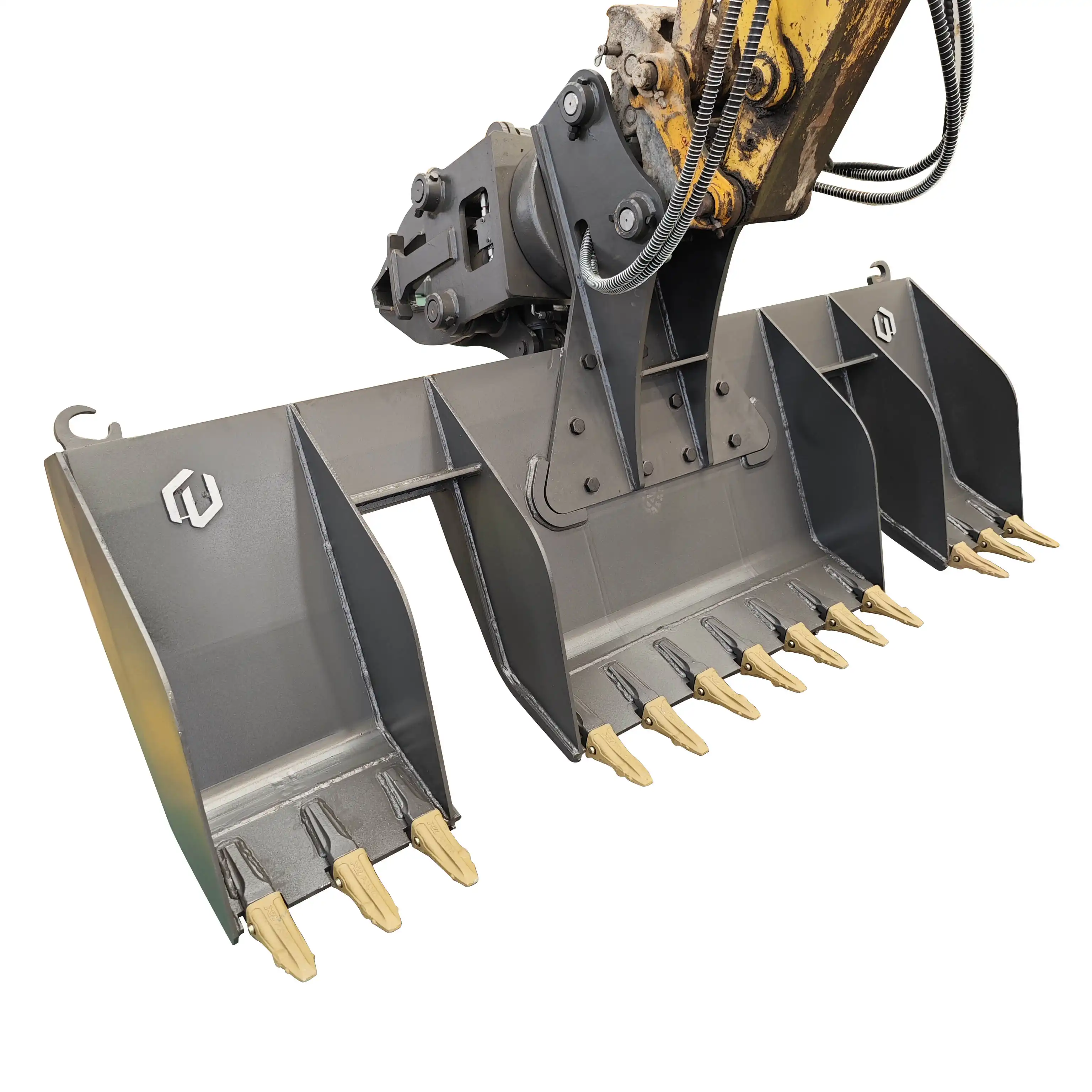

Tiannuo Machinery offers a comprehensive range of excavator grab arms designed to meet diverse needs across various industries. Our grab arms are engineered for superior performance in applications such as dock unloading, railway transportation unloading, and waste steel handling. With beveling welding to prevent deformation, our products ensure durability and reliability in demanding environments.

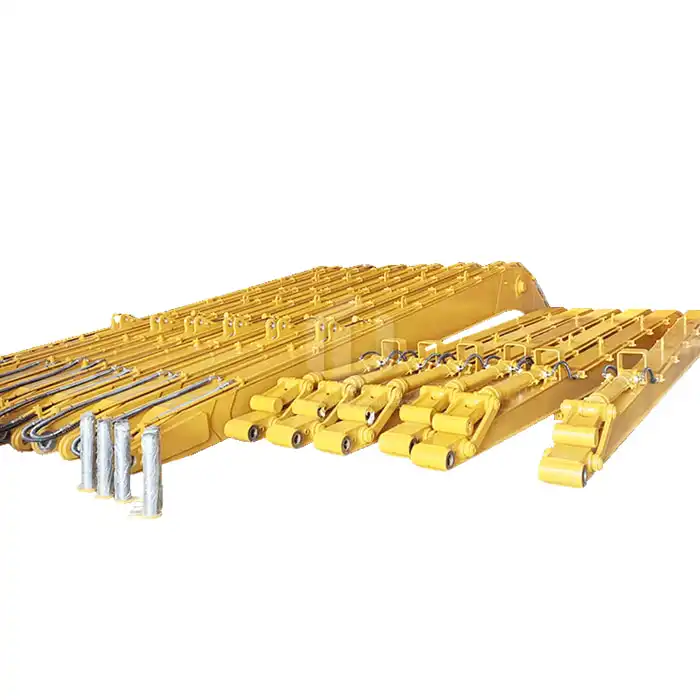

Our grab arms are available for a wide range of excavator tonnages, including:

- 12-16 tons

- 20-27 tons

- 30-38 tons

- 40-49 tons

At Tiannuo Machinery, we understand that every project has unique requirements. That's why we offer customizable designs, allowing you to tailor arm length, lifting capacity, and attachment configurations to your specific needs. Our team of experts is dedicated to helping you find the perfect solution for your excavator and application.

If you're in the process of choosing a grab arm manufacturer, we invite you to experience the Tiannuo difference. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry. To discuss your requirements or request a quotation, please don't hesitate to reach out to our dedicated team:

- Manager: arm@stnd-machinery.com

- Sales Team: rich@stnd-machinery.com and tn@stnd-machinery.com

Let Tiannuo Machinery be your partner in enhancing your excavator's capabilities with our state-of-the-art grab arms. Contact us today to take the first step towards optimizing your operations and achieving new levels of efficiency in your projects.

References

Smith, J. & Brown, A. (2020). Excavator Attachments: A Comprehensive Guide to Selection and Application. Construction Equipment Press.

Johnson, R. (2019). Hydraulic Systems in Construction Machinery: Design and Optimization. Engineering Solutions Journal.

Lee, S. & Patel, M. (2021). Material Handling Efficiency: The Role of Excavator Grab Arms in Modern Construction. International Journal of Construction Management.

Tiannuo Machinery. (2023). Product Catalog: Excavator Grab Arms and Attachments.