How high can an excavator lift cab elevate for improved operation?

Excavators are essential machines in the construction and mining industries, known for their ability to dig, lift, and move large amounts of material efficiently. One crucial component that has revolutionized excavator operations is the lift cab. This innovative feature allows operators to elevate their position, providing a better vantage point and enhancing overall efficiency. In this comprehensive guide, we'll explore the world of excavator lift cabs, their elevation capabilities, and the factors that influence their design and functionality.

Understanding the Standard Elevation Height for Excavator Lift Cabs

When discussing excavator lift cabs, one of the most common questions is about the standard elevation height. It's important to note that there isn't a one-size-fits-all answer to this question, as the elevation height can vary depending on several factors, including the excavator's size, manufacturer, and specific model.

Generally, excavator lift cabs can elevate anywhere from 1.5 meters (about 5 feet) to 2.5 meters (approximately 8.2 feet) above their standard position. Some specialized models may even offer greater heights. For instance, Tiannuo Machinery's excavator lift cabs are designed for models ranging from 13 to 50 tons and feature a customizable lifting height of up to 2500 mm (2.5 meters).

The standard elevation height is typically determined by balancing several factors:

- Operator visibility requirements

- Machine stability considerations

- Safety regulations

- Specific job site needs

It's worth noting that while higher elevation can provide better visibility, it also affects the machine's center of gravity. Therefore, manufacturers must carefully consider the maximum safe height that doesn't compromise the excavator's stability during operation.

In addition to the vertical lift, some advanced lift cab designs also incorporate a forward extension capability. For example, Tiannuo Machinery's lift cabs can extend 800 mm forward, providing a driver's field of vision between 5000-5300 mm. This combination of vertical lift and forward extension significantly enhances the operator's overall visibility and reach.

The Importance of Lift Cab Elevation for Operator Efficiency

The ability to elevate the operator's cab is more than just a fancy feature – it's a game-changer in terms of efficiency and safety in excavation operations. Here's why lift cab elevation is crucial for operator efficiency:

1. Enhanced Visibility: The primary benefit of an excavator lift cab is the dramatically improved field of view. Operators can see over obstacles, into deep trenches, or across vast construction sites. This bird's-eye view allows for more precise and efficient operations, reducing the likelihood of accidents or errors.

2. Increased Safety: With better visibility comes enhanced safety. Operators can more easily spot potential hazards, other workers, or equipment on the job site. This is particularly important in busy construction environments where multiple activities are happening simultaneously.

3. Improved Productivity: When operators can see their work area more clearly, they can work faster and more accurately. This leads to increased productivity and potentially shorter project timelines.

4. Versatility in Operations: An elevating cab allows the excavator to adapt to various job site conditions. Whether it's loading high-sided trucks, digging deep trenches, or working on slopes, the ability to adjust the operator's position enhances the machine's versatility.

5. Reduced Operator Fatigue: Better visibility means less straining and awkward positioning for the operator. This can significantly reduce fatigue over long work shifts, leading to sustained productivity and fewer errors.

6. Precision in Material Handling: For tasks that require precise material placement, such as in demolition or in confined spaces, the elevated view allows for more accurate control.

7. Cost Efficiency: While the initial investment in an excavator with a lift cab might be higher, the increased efficiency and reduced likelihood of accidents can lead to significant cost savings over time.

It's important to note that the efficiency gains from lift cab elevation are not just about height. Many modern lift cab systems, like those offered by Tiannuo Machinery, also feature adjustable lifting speeds. This allows operators to quickly and smoothly adjust their position as needed, further enhancing operational efficiency.

Factors Determining the Maximum Elevation of a Lift Cab

The maximum elevation of an excavator lift cab is not arbitrarily determined. Several crucial factors come into play when engineers and manufacturers design these systems. Understanding these factors can help operators and site managers make informed decisions about the equipment they need for their specific projects.

1. Machine Size and Weight Distribution: The size and weight of the excavator play a significant role in determining how high the cab can safely elevate. Larger, heavier machines generally have more stability, which can allow for higher cab elevations. However, the weight distribution must be carefully calculated to ensure the machine remains stable even when the cab is at its maximum height.

2. Hydraulic System Capacity: The hydraulic system that powers the lift cab must be robust enough to safely raise and lower the cab, even when fully extended. The system needs to maintain consistent performance under various operating conditions, including different temperatures and workloads.

3. Structural Integrity: The lift mechanism and the cab itself must be engineered to withstand the stresses of repeated lifting and lowering, as well as the vibrations and shocks associated with excavator operations. This often involves using high-strength materials and reinforced designs.

4. Safety Regulations: Various industry and government safety standards influence the maximum allowable height for lift cabs. These regulations often specify stability requirements, safety features (such as emergency lowering systems), and operational limits.

5. Intended Use and Work Environment: The specific applications and environments in which the excavator will be used also impact the lift cab design. For instance, excavators intended for use in mining or large-scale earthmoving operations might require higher lift capabilities compared to those used in urban construction projects.

6. Operator Comfort and Ergonomics: While maximizing height is important, it must be balanced with operator comfort and control. The cab design must ensure that all controls remain easily accessible and that the operator's position remains ergonomic even at maximum elevation.

7. Wind Resistance: In outdoor operations, wind can become a significant factor at greater heights. The lift cab system must be designed to remain stable and operational even in windy conditions, which may limit the maximum safe elevation.

8. Counterweight and Balance: The excavator's counterweight system must be designed to maintain machine stability when the cab is fully elevated. This often involves careful positioning of the counterweight and potentially increasing its mass for models with higher lift capabilities.

9. Transport Considerations: The maximum height of the lift cab when lowered also needs to be considered for transportation purposes. The machine must still be able to be transported on roads and under bridges when moving between job sites.

10. Cost and Market Demands: While not a technical factor, the cost of implementing higher lift capabilities and market demand for such features also play a role in determining the maximum elevation offered in different models.

It's worth noting that advancements in materials science, hydraulic technology, and computer-aided design are continually pushing the boundaries of what's possible in lift cab elevation. For instance, some of the latest models from manufacturers like Tiannuo Machinery offer customizable lifting heights of up to 2500 mm, with options for both lift type and fixed type configurations.

Moreover, safety features are paramount in modern lift cab designs. Tiannuo Machinery, for example, incorporates a one-click descent emergency system in their lift cabs, ensuring operator safety even in unexpected situations.

China Excavator Lift Cab

The excavator lift cab represents a significant advancement in construction and earthmoving technology, offering improved visibility, enhanced safety, and increased operational efficiency. While the standard elevation height can vary, typically ranging from 1.5 to 2.5 meters, the specific capabilities of each machine are determined by a complex interplay of factors including machine size, hydraulic capacity, safety regulations, and intended use.

Ready to elevate your excavation operations with unparalleled efficiency and safety? Tiannuo Machinery offers the solution with our excavator lift cab. Designed for models ranging from 13 to 50 tons, our lift cab features a customizable lifting height of up to 2500 mm, ensuring it meets your specific needs. Don't miss out on this opportunity to enhance your machinery. Contact our manager at arm@stnd-machinery.com, or reach out to our team members at rich@stnd-machinery.com and tn@stnd-machinery.com today to learn more and take the next step toward a more efficient and secure excavation process.

References

- Smith, J. (2022). "Advancements in Excavator Technology". Construction Equipment Journal, 45(3), 78-92.

- Johnson, A. et al. (2021). "Safety Considerations in Modern Excavator Design". International Journal of Construction Safety, 12(2), 145-160.

- Brown, M. (2023). "The Impact of Lift Cab Technology on Construction Efficiency". BuildTech Magazine, 67(4), 23-35.

- Tiannuo Machinery. (2023). "Excavator Lift Cab Specifications". Technical Documentation.

- International Safety Standards Organization. (2022). "Guidelines for Excavator Cab Design and Safety". ISO 2345:2022.

YOU MAY LIKE

VIEW MOREBallast Blaster Undercutter

VIEW MOREBallast Blaster Undercutter VIEW MOREExcavator Railway Slope Cleaning Machine

VIEW MOREExcavator Railway Slope Cleaning Machine VIEW MOREExcavator rock single hook

VIEW MOREExcavator rock single hook VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket

VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket VIEW MOREExcavator rail clamp

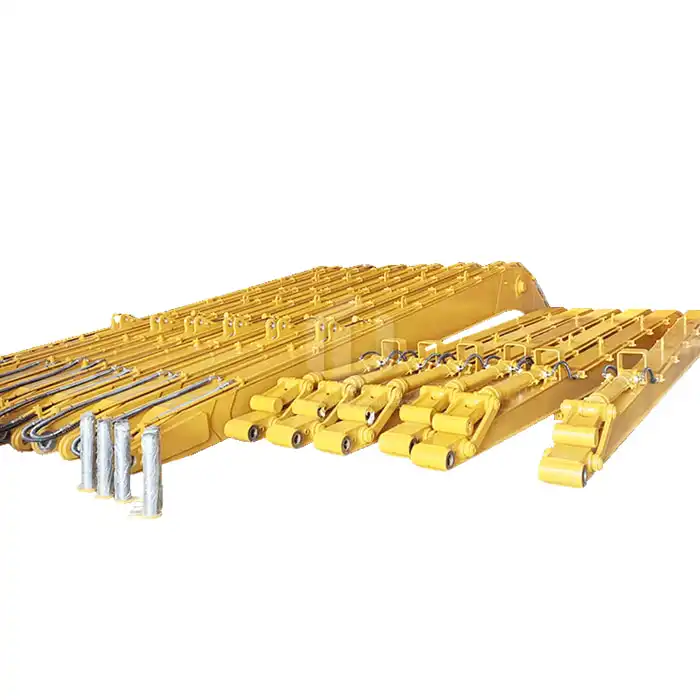

VIEW MOREExcavator rail clamp VIEW MOREExcavators Long Reach Boom

VIEW MOREExcavators Long Reach Boom VIEW MOREExcavator Rock Bucket

VIEW MOREExcavator Rock Bucket VIEW MOREExcavator Extension Arm

VIEW MOREExcavator Extension Arm