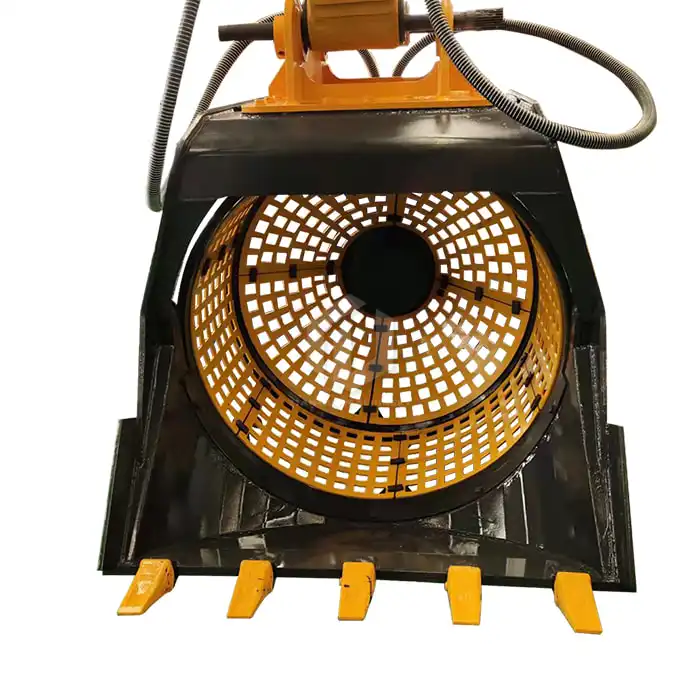

Excavator Vibratory Compactor For Sale

When it comes to construction and earthwork projects, having the right equipment can make all the difference in efficiency, quality, and cost-effectiveness. One such essential piece of machinery is the excavator vibratory compactor. These versatile attachments play a crucial role in soil compaction, foundation preparation, and various other construction applications.

How to Choose the Right Excavator Vibratory Compactor for Your Project?

Selecting the appropriate excavator vibratory compactor is crucial for ensuring optimal performance and achieving the desired results in your construction project. Here are several key factors to consider when making your choice:

1. Excavator Compatibility: First and foremost, ensure that the vibratory compactor is compatible with your excavator. Check the excavator's hydraulic flow and pressure requirements and match them with the compactor's specifications. This compatibility is essential for proper operation and to prevent damage to both the excavator and the attachment.

2. Compaction Force: The compaction force, measured in kilograms or tons, determines the compactor's ability to densify soil effectively. Consider the type of soil you'll be working with and the required compaction density to choose a compactor with adequate force. For instance, cohesive soils like clay may require higher compaction forces compared to granular soils.

3. Frequency: The vibration frequency of the compactor affects its performance on different soil types. Higher frequencies are generally more effective for granular soils, while lower frequencies work better for cohesive soils. Look for a compactor with adjustable frequency settings for versatility across various soil conditions.

4. Plate Size: The size of the compactor plate influences the area you can compact in a single pass. Larger plates cover more ground but may sacrifice maneuverability in tight spaces. Consider the typical job sites you work on and choose a plate size that balances efficiency with accessibility.

5. Weight: The weight of the vibratory compactor affects both its compaction performance and the excavator's lifting capacity. Ensure that your excavator can safely handle the weight of the compactor, including any additional counterweights if necessary.

6. Durability and Build Quality: Look for compactors made with high-quality materials and robust construction. Features like reinforced housings, protected hydraulic components, and wear-resistant compaction plates contribute to longevity and reduced maintenance needs.

7. Versatility: Some vibratory compactors come with interchangeable plates or attachments for different applications. If your projects vary widely, consider a model that offers this flexibility to adapt to various tasks.

8. Manufacturer Reputation: Choose a compactor from a reputable manufacturer known for quality and reliability. Research customer reviews, ask for recommendations from industry peers, and consider the availability of parts and service support in your area.

By carefully evaluating these factors, you can select an excavator vibratory compactor that not only meets your current project requirements but also serves as a valuable asset for future endeavors.

What Are the Differences Between New and Used Excavator Vibratory Compactors?

When in the market for an excavator vibratory compactor, you'll likely face the decision between purchasing a new or used model. Both options have their merits and drawbacks, and understanding these differences can help you make an informed choice that aligns with your budget and project needs.

New Excavator Vibratory Compactors:

1. Latest Technology: New compactors often feature the most recent advancements in compaction technology, potentially offering improved efficiency and performance.

2. Warranty Coverage: Manufacturers typically provide comprehensive warranties for new equipment, giving you peace of mind and protection against unexpected issues.

3. Optimal Condition: A new compactor ensures you're starting with a pristine machine, free from wear and tear or potential hidden problems.

4. Customization Options: When purchasing new, you may have more flexibility to select specific features or configurations that suit your exact needs.

5. Higher Initial Cost: The primary drawback of new compactors is their higher upfront cost compared to used models.

Used Excavator Vibratory Compactors:

1. Cost Savings: Used compactors are generally more budget-friendly, allowing you to acquire equipment at a lower initial investment.

2. Immediate Availability: Used models are often readily available, which can be advantageous if you need equipment quickly for an upcoming project.

3. Proven Performance: A well-maintained used compactor with a good track record can offer reliable performance at a fraction of the cost of a new model.

4. Depreciation Advantage: Used equipment has already undergone its steepest depreciation, potentially offering better value retention.

5. Potential for Hidden Issues: The main risk with used compactors is the possibility of underlying problems or wear that may not be immediately apparent.

6. Limited Warranty: Used equipment often comes with limited or no warranty coverage, increasing the risk of out-of-pocket repair costs.

When deciding between new and used excavator vibratory compactors, consider factors such as your budget, project requirements, and long-term plans. If you opt for a used model, thoroughly inspect the equipment, review its maintenance history, and consider having it evaluated by a professional before purchase. For new compactors, research different manufacturers and models to ensure you're getting the best value for your investment.

What Factors Affect the Cost of an Excavator Vibratory Compactor?

Understanding the factors that influence the cost of an excavator vibratory compactor can help you budget effectively and make an informed purchasing decision. Here are the key elements that contribute to the overall price:

1. Size and Capacity: Larger compactors with higher compaction forces generally come with a higher price tag. The size and capacity should align with your typical project requirements to ensure you're not overpaying for unnecessary power or underpowered for your needs.

2. Brand and Manufacturer: Well-established brands with a reputation for quality and reliability often command premium prices. However, these higher costs may be justified by better performance, durability, and after-sales support.

3. Technology and Features: Advanced features such as variable frequency settings, automatic load sensing, or remote operation capabilities can increase the cost but may offer improved efficiency and versatility.

4. Material Quality: Compactors made with high-grade steel and premium components will typically be more expensive but may offer better longevity and performance over time.

5. New vs. Used: As discussed earlier, new compactors generally cost more than used ones. The price difference can be significant, but it's essential to weigh this against factors like warranty coverage and expected lifespan.

6. Market Demand: Like any product, the price of excavator vibratory compactors can fluctuate based on market demand. High demand periods may lead to price increases, while slower periods might offer opportunities for better deals.

7. Geographical Location: Prices can vary depending on your location due to factors such as shipping costs, local competition among dealers, and regional economic conditions.

8. Customization: If you require specific modifications or custom features, these additions will likely increase the overall cost of the compactor.

9. Warranty and Service Packages: Extended warranties or comprehensive service agreements can add to the initial cost but may provide long-term savings and peace of mind.

10. Financing Options: The availability and terms of financing can affect the total cost of ownership. Favorable financing terms might make a more expensive model more accessible, while high-interest rates could significantly increase the long-term cost.

11. Regulatory Compliance: Compactors that meet stringent environmental or safety standards may come at a premium but could be necessary for certain projects or regions.

12. Included Accessories: Some manufacturers may include additional accessories or attachments in the package, affecting the overall value proposition and price.

When evaluating the cost of an excavator vibratory compactor, it's crucial to consider not just the initial purchase price but also the total cost of ownership. This includes factors like fuel efficiency, maintenance requirements, and expected lifespan. A more expensive compactor might prove more economical in the long run if it offers better reliability and lower operating costs.

China Excavator Vibratory Compactor Manufacturers

The excavator vibratory compactor market has seen significant growth and innovation, with manufacturers from various countries contributing to advancements in the field. Among these, China excavator vibratory compactor manufacturers have emerged as key players, offering a wide range of products that combine quality, affordability, and technological innovation.

One notable example is Tiannuo Machinery, a leading China excavator vibratory compactor manufacturer. Their product line includes compactors ranging from 2000 to 4000 kg, catering to various project sizes and requirements. These compactors boast impressive construction speeds ranging from 2 to 4 m/min, ensuring efficient and timely project completion.

If you're in the market for a reliable and cost-effective excavator vibratory compactor, considering options from Chinese manufacturers like Tiannuo Machinery could be a wise choice. Their products offer a balance of performance and value that can benefit a wide range of construction and earthwork projects.

For more information or to discuss your specific needs, we encourage you to reach out to the Tiannuo Machinery team. You can contact their manager at arm@stnd-machinery.com, or get in touch with team members at rich@stnd-machinery.com and tn@stnd-machinery.com. Their expertise can help guide you towards the perfect excavator vibratory compactor solution for your projects.

References:

[1] Caterpillar. (2021). "Compaction Equipment Selection Guide." Caterpillar Inc.

[2] Construction Equipment. (2020). "New vs. Used Construction Equipment: Pros and Cons." Construction Equipment Magazine.

[3] American Rental Association. (2019). "Total Cost of Ownership in Equipment Acquisition." ARA Rental Market Monitor.