Excavator Railway Slope Cleaning Machine Manual

Railway maintenance is a critical aspect of ensuring safe and efficient train operations. One of the essential tasks in this domain is keeping railway slopes clean and well-maintained. The excavator railway slope cleaning machine has revolutionized this process, making it faster, more efficient, and cost-effective. In this comprehensive guide, we'll explore the ins and outs of this innovative machine, covering its manual, overview, technical specifications, and setup process.

Machine Overview

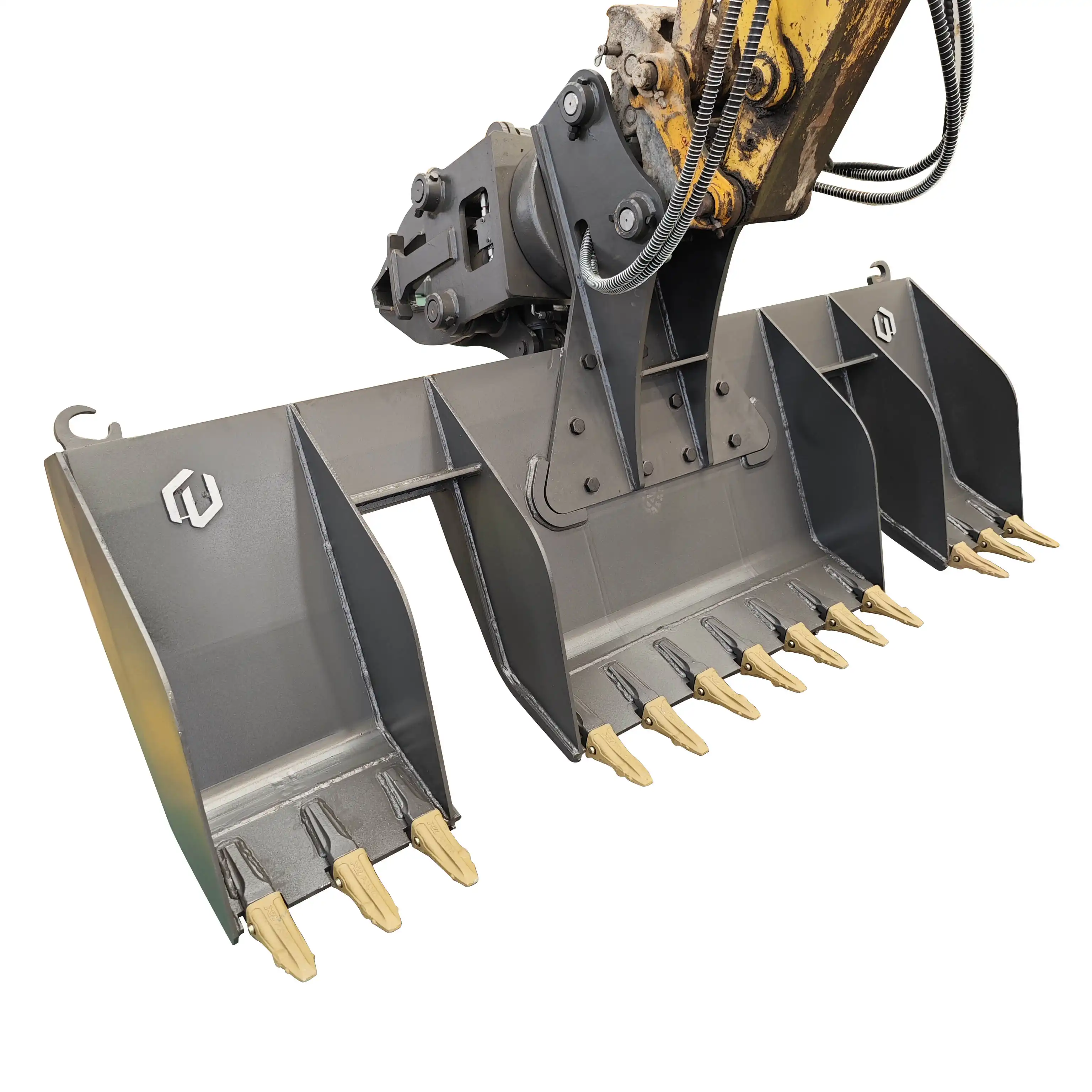

The excavator railway slope cleaning machine is a specialized piece of equipment designed to clean, shape, and maintain the slopes on either side of railway tracks. This versatile machine combines the power and mobility of an excavator with custom attachments tailored for railway slope maintenance.

One of the key advantages of the excavator railway slope cleaning machine is its ability to work efficiently in challenging terrains. The machine can navigate steep slopes and uneven surfaces, ensuring thorough cleaning and maintenance of railway embankments. This capability is crucial for preventing erosion, maintaining proper drainage, and ensuring the overall stability of the railway infrastructure.

The machine typically comes in two main variants: the broad knife type and the rotating scraper type. The broad knife type uses a wide, flat blade to scrape and level the slope surface, while the rotating scraper type employs a cylindrical drum with multiple teeth or blades that rotate to clean and shape the slope.

Both types offer unique advantages, and the choice between them often depends on the specific requirements of the railway line and the surrounding terrain. The broad knife type is generally more suitable for larger, flatter areas, while the rotating scraper type excels in handling more varied and uneven surfaces.

One of the standout features of the excavator railway slope cleaning machine is its adjustable angle mechanism. This allows operators to fine-tune the cleaning angle to match the exact slope of the railway embankment, ensuring optimal cleaning results and minimizing the risk of damage to the underlying structure.

Technical Specifications

Understanding the technical specifications of the excavator railway slope cleaning machine is crucial for railway maintenance teams and operators. These specifications not only highlight the machine's capabilities but also help in determining its suitability for specific railway maintenance projects.

The exact specifications may vary depending on the manufacturer and model, but here are some key parameters typically associated with excavator railway slope cleaning machines:

- Operating Weight: Usually ranges from 20 to 30 tons, depending on the base excavator model.

- Engine Power: Typically between 150 to 250 horsepower, providing ample power for both movement and cleaning operations.

- Cleaning Width: This can vary from 2 to 4 meters, allowing for efficient coverage of railway slopes.

- Cleaning Depth: Generally adjustable, with a maximum depth of around 300mm.

- Slope Angle Range: Most machines can handle slopes ranging from 0 to 45 degrees.

- Rotation Speed: For rotating scraper types, the drum typically rotates at 100 to 200 RPM.

- Hydraulic System: Usually features a high-pressure hydraulic system with flow rates of 200-300 liters per minute.

These specifications underscore the machine's robust design and versatility. The high engine power ensures that the machine can operate effectively even on steep slopes, while the adjustable cleaning depth allows for customized maintenance based on the specific needs of different railway sections.

The hydraulic system is a critical component, providing the necessary power for both the cleaning mechanism and the angle adjustment feature. This system allows for smooth, precise control of the cleaning attachment, enhancing the overall efficiency and effectiveness of the maintenance process.

It's worth noting that many manufacturers offer customization options, allowing railway companies to tailor the specifications to their specific needs. This flexibility ensures that the excavator railway slope cleaning machine can be optimized for a wide range of railway environments and maintenance requirements.

Setup and Installation: Getting Your Machine Ready for Action

Proper setup and installation of the excavator railway slope cleaning machine are crucial for ensuring its optimal performance and longevity. While the exact process may vary depending on the specific model and manufacturer, here are the general steps involved:

- Site Preparation: Before bringing in the machine, ensure that the railway site is properly prepared. This includes clearing any debris or obstacles that might interfere with the machine's operation.

- Transportation: The machine is typically transported to the site on a lowboy trailer. Ensure that the transportation route can accommodate the size and weight of the machine.

- Unloading: Use appropriate equipment, such as a crane or ramp, to safely unload the machine from the transport vehicle.

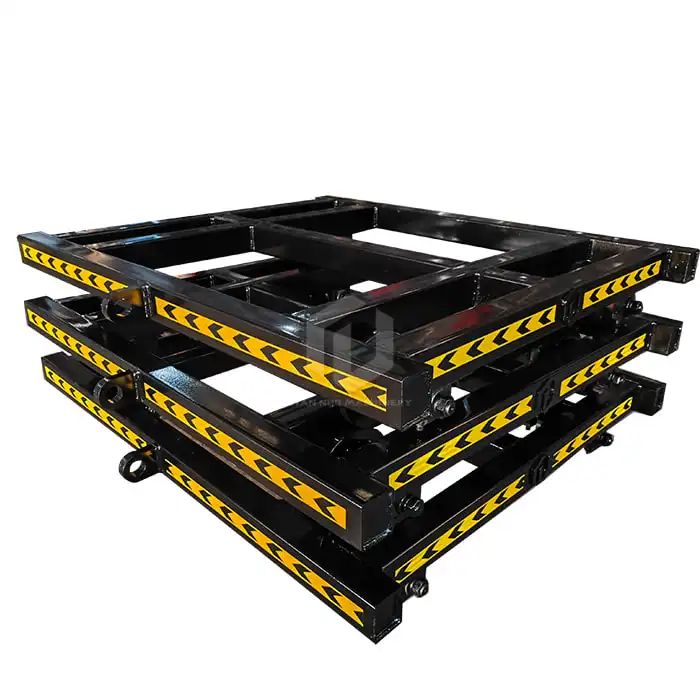

- Assembly: If the cleaning attachment is shipped separately, it will need to be attached to the excavator base. This process usually involves connecting hydraulic lines and securing the attachment mechanically.

- Calibration: Once assembled, the machine needs to be calibrated. This includes setting the correct cleaning angle, depth, and rotation speed (for rotating scraper types).

- Testing: Before full deployment, conduct a series of tests to ensure all systems are functioning correctly. This includes checking the hydraulic system, testing the cleaning mechanism, and verifying the angle adjustment feature.

- Operator Training: Ensure that all operators are thoroughly trained on the machine's features, controls, and safety procedures. This is crucial for both efficient operation and workplace safety.

- Safety Checks: Perform a comprehensive safety check, including verifying all safety features, emergency stop mechanisms, and warning systems.

It's important to note that the setup and installation process should always be carried out by qualified professionals, preferably technicians certified by the machine's manufacturer. This ensures that the machine is set up correctly and safely, minimizing the risk of operational issues or accidents.

Regular maintenance is also a crucial part of keeping the excavator railway slope cleaning machine in optimal condition. This includes routine checks of the hydraulic system, cleaning mechanism, and base excavator components. Adhering to the manufacturer's recommended maintenance schedule can significantly extend the machine's lifespan and maintain its performance over time.

Excavator Railway Slope Cleaning Machine

The excavator railway slope cleaning machine represents a significant advancement in railway maintenance technology. Its ability to efficiently clean and shape railway slopes not only improves the aesthetic appearance of railway lines but also plays a crucial role in ensuring their safety and longevity.

By combining the versatility of an excavator with specialized cleaning attachments, this machine offers a comprehensive solution for railway slope maintenance. Whether you're dealing with steep embankments, varied terrain, or challenging weather conditions, the excavator railway slope cleaning machine is up to the task.

If you're in the market for an excavator railway slope cleaning machine, consider Tiannuo Machinery. Their machines are suitable for cleaning, shaping, and maintaining ballast on both sides of railway lines. They offer both broad knife and rotating scraper types, with freely adjustable angles to suit various slope requirements.

For more information or to discuss your specific needs, don't hesitate to reach out to Tiannuo Machinery. You can contact their manager at arm@stnd-machinery.com, or get in touch with their team at rich@stnd-machinery.com and tn@stnd-machinery.com. Their expert team will be happy to help you find the perfect solution for your railway maintenance needs.

References

- Railway Technology. (2021). "Railway Maintenance Equipment: Trends and Innovations."

- International Railway Journal. (2020). "Advancements in Railway Slope Maintenance."

- Railway Engineering. (2019). "Best Practices in Railway Embankment Maintenance."

- Journal of Rail Transport Planning & Management. (2018). "The Role of Specialized Equipment in Modern Railway Maintenance."