Excavator Gripper Types

Excavator grippers are essential attachments that enhance the versatility and efficiency of excavators in various industries. These specialized tools enable operators to handle a wide range of materials with precision and power.

Versatility of Excavator Grippers

Excavator grippers, also known as excavator grapples or clamps, are designed to extend the capabilities of standard excavators. These attachments allow machines to grasp, move, and manipulate various materials, from logs and debris to rocks and scrap metal. Their versatility makes them indispensable in industries such as forestry, construction, demolition, and recycling.

One of the primary advantages of using excavator grippers is their ability to increase productivity and efficiency on job sites. By eliminating the need for manual handling of heavy or awkward materials, these attachments reduce labor costs and minimize the risk of workplace injuries. Additionally, they can perform multiple tasks, such as sorting, loading, and stacking, which streamlines operations and reduces the need for specialized equipment.

When selecting an excavator gripper, it's crucial to consider factors such as the specific application, material density, and the excavator's size and hydraulic capacity. Different types of grippers are designed to handle various materials and tasks, ensuring optimal performance and durability in diverse working conditions.

Wood Grab: Precision and Power in Forestry Operations

Wood grabs, also known as log grapples, are specifically designed for handling logs, tree limbs, and other wooden materials. These excavator grippers are widely used in forestry operations, lumber yards, and land clearing projects. Wood grabs feature strong, curved tines that securely grip logs of various sizes, allowing for efficient loading, unloading, and stacking of timber.

Key features of wood grabs include:

- Curved tines for secure gripping of round logs

- High-strength steel construction for durability

- Large opening capacity to accommodate various log sizes

- Rotation capability for precise positioning

Wood grabs offer several benefits in forestry and logging operations:

- Increased productivity in log handling and sorting

- Reduced risk of damage to valuable timber

- Improved safety by minimizing manual handling of heavy logs

- Enhanced versatility for various forestry tasks

When choosing a wood grab, consider factors such as the average log size in your operations, the required gripping force, and the compatibility with your excavator model. Some wood grabs also feature interchangeable tines or adjustable openings to accommodate different log diameters, providing greater flexibility in various applications.

Rock Grab: Tackling Tough Terrain in Construction and Mining

Rock grabs, also known as stone grapples or boulder grapples, are robust excavator grippers designed to handle large rocks, boulders, and other dense materials. These attachments are commonly used in construction, quarrying, and mining operations, where they play a crucial role in material handling, site preparation, and load-out processes.

Key features of rock grabs include:

- Heavy-duty construction to withstand high-impact loads

- Reinforced tines or jaws for increased durability

- Large gripping capacity for handling oversized rocks

- Serrated edges for improved grip on irregular surfaces

Rock grabs offer several advantages in challenging terrain and heavy-duty applications:

- Efficient handling of large, irregularly shaped rocks and boulders

- Improved safety by reducing the need for manual rock handling

- Increased productivity in site clearing and material sorting

- Versatility in handling various types of dense materials

When selecting a rock grab, it's essential to consider the size and weight of the materials you'll be handling, as well as the excavator's lifting capacity. Some rock grabs feature adjustable jaw openings or interchangeable teeth to accommodate different material sizes and shapes, providing greater flexibility in diverse applications.

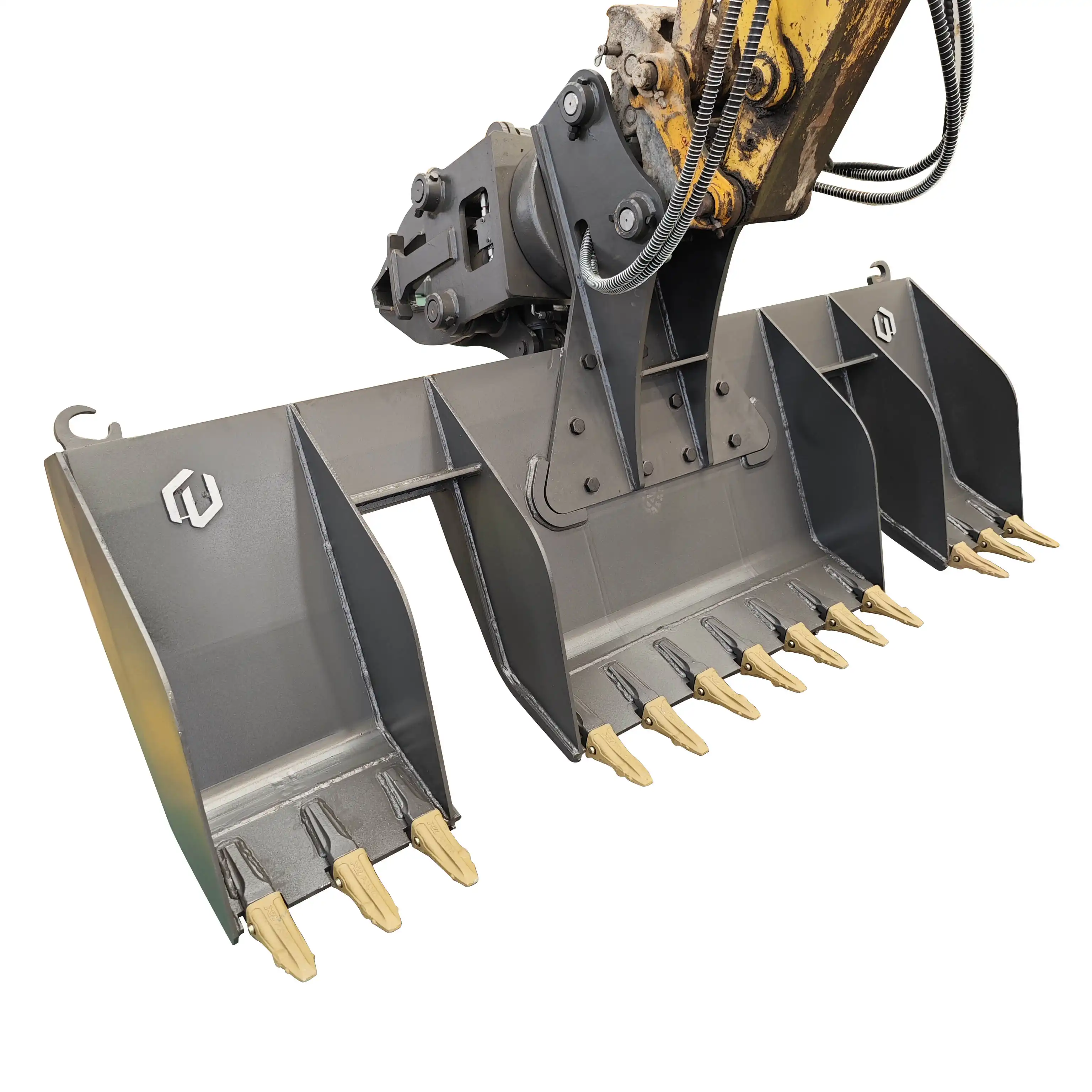

Hydraulic Clamp: Precision and Versatility in Material Handling

Hydraulic clamps are versatile excavator grippers that offer precise control and adaptability in various material handling tasks. These attachments use hydraulic power to open and close the clamp jaws, allowing for secure gripping and controlled release of materials. Hydraulic clamps are widely used in construction, demolition, recycling, and general material handling applications.

Key features of hydraulic clamps include:

- Adjustable gripping force for handling different materials

- Smooth, controlled operation for precise positioning

- Interchangeable jaw plates for various applications

- 360-degree rotation capability for enhanced maneuverability

Hydraulic clamps offer numerous benefits in diverse work environments:

- Versatility in handling a wide range of materials and shapes

- Improved efficiency in sorting and loading operations

- Reduced risk of material damage due to controlled gripping force

- Enhanced safety through precise material placement

When choosing a hydraulic clamp, consider factors such as the required gripping force, jaw opening range, and compatibility with your excavator's hydraulic system. Some hydraulic clamps feature quick-change systems for easy attachment swapping, allowing operators to adapt to different tasks quickly and efficiently.

China Excavator Gripper

The excavator gripper, manufactured by Tiannuo Machinery, is a versatile attachment designed for various heavy-duty tasks. It features a robust Clamp Body made from high-strength steel, ensuring durability and reliability in demanding environments. The adjustable clamp teeth allow for customization to suit different tasks, making it adaptable to a wide range of applications. The Oil Cylinder powers the clamping action through hydraulic oil, providing strong and precise control. A Pipeline connects the cylinder to the control valve, facilitating smooth operation. The hydraulic system efficiently controls the clamp movement using pressure oil, enabling efficient excavation, demolition, ore extraction, and slope cleaning.

If you are choosing your excavator gripper manufacturer, we welcome you to contact our team. Our manager's email is arm@stnd-machinery.com, and the team's emails are rich@stnd-machinery.com and tn@stnd-machinery.com. We look forward to assisting you in finding the perfect excavator gripper solution for your specific needs.

References

- Smith, J. (2021). "Advanced Excavator Attachments: A Comprehensive Guide." Construction Equipment Journal, 45(3), 78-92.

- Johnson, L. M., & Brown, R. K. (2020). "Innovations in Forestry Equipment: Enhancing Productivity and Safety." Journal of Forest Engineering, 31(2), 115-130.

- Miller, A. (2022). "Hydraulic Attachments in Modern Construction: Applications and Advancements." International Journal of Construction Technology, 17(4), 203-218.

- Thompson, E. R., & Davis, S. L. (2019). "Rock Handling Techniques in Quarrying Operations: A Comparative Study." Mining Engineering Review, 28(1), 45-60.

- Wilson, G. H. (2023). "Material Handling Efficiency in Recycling Facilities: The Role of Specialized Attachments." Waste Management & Research, 41(2), 189-204.