Do the suppliers provide customized excavator grippers?

In the world of construction and excavation, having the right tools for the job is crucial. Excavator grippers are essential attachments that significantly enhance the versatility and efficiency of excavators. While standard grippers are widely available, many operators and construction companies find themselves in need of specialized solutions. This brings us to an important question: Do excavator gripper suppliers provide customized options? Let's delve into this topic and explore the world of customized excavator grippers.

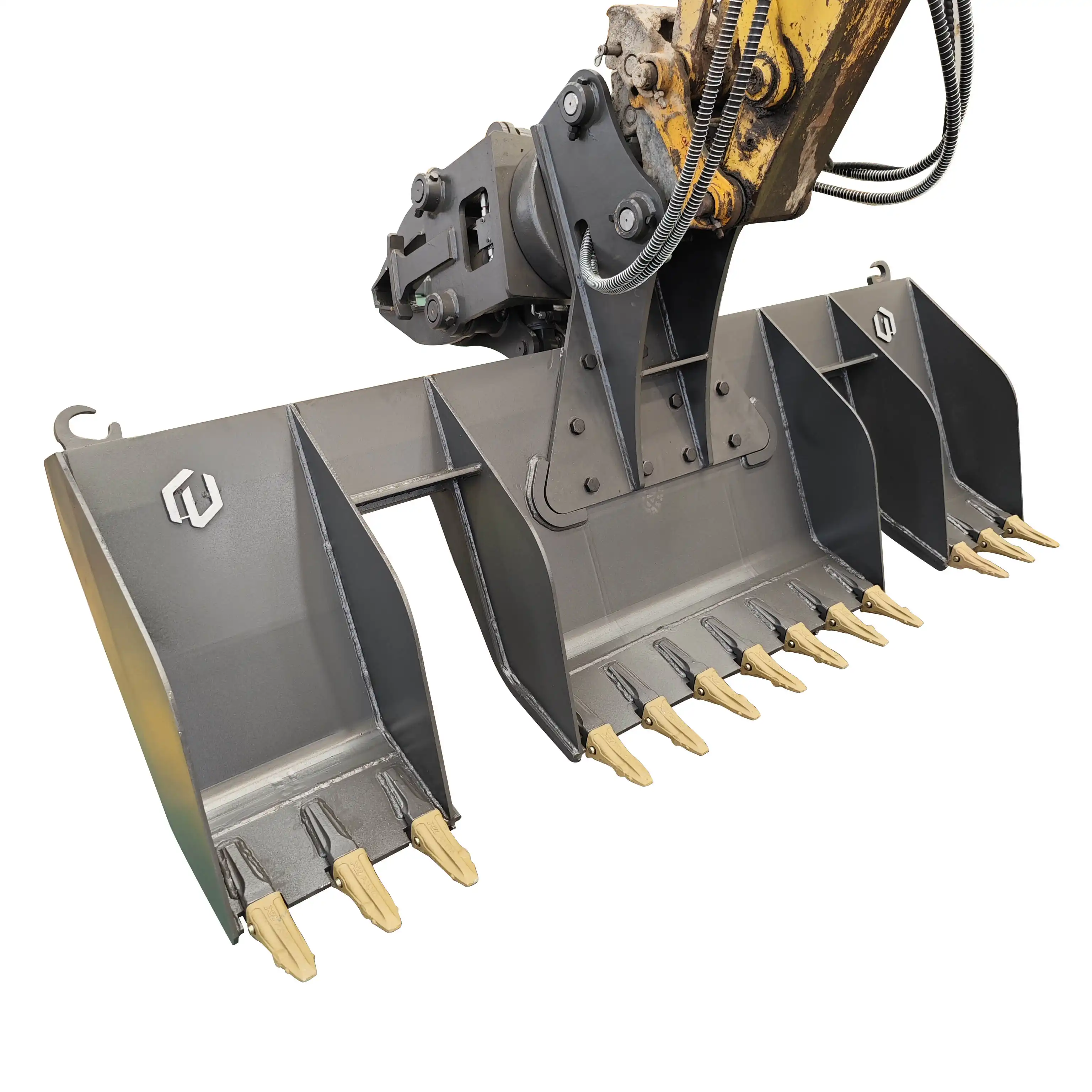

Excavator grippers, also known as excavator grapples or clamps, are hydraulic attachments designed to grasp, hold, and manipulate various materials. These versatile tools are used in a wide range of applications, from construction and demolition to forestry and waste management. As the demands of these industries evolve, so does the need for specialized equipment.

Advantages of opting for customized excavator grippers

Customized excavator grippers offer numerous benefits that can significantly impact productivity and efficiency on job sites. Let's explore some of the key advantages:

1. Tailored to specific tasks: Custom grippers can be designed to handle unique materials or perform specialized functions. For instance, a company working in the recycling industry might require a gripper with specific tooth configurations to efficiently sort and handle different types of waste materials.

2. Improved efficiency: By having a gripper that's precisely matched to your excavator and intended use, you can optimize your operations. This can lead to faster work cycles, reduced downtime, and increased overall productivity.

3. Enhanced safety: Customized grippers can be designed with additional safety features or modifications that address specific workplace hazards, thereby improving operator safety and reducing the risk of accidents.

4. Cost-effective in the long run: While custom solutions may have a higher initial cost, they can prove more economical over time. A well-designed custom gripper can last longer, require less maintenance, and perform more efficiently than a standard model forced to adapt to unsuitable tasks.

5. Competitive advantage: Having specialized equipment can set your company apart from competitors. It demonstrates your commitment to efficiency and your ability to handle unique or challenging projects.

6. Adaptability to unique environments: Custom grippers can be designed to perform optimally in specific environmental conditions, such as extreme temperatures, corrosive environments, or underwater operations.

These advantages highlight why many companies choose to work with excavator gripper suppliers who offer customization options. The ability to tailor equipment to specific needs can have a significant impact on a company's operations and bottom line.

The customization options offered by gripper suppliers

Excavator gripper suppliers understand the diverse needs of their clients and often provide a range of customization options. These can include:

1. Size and capacity: Grippers can be customized to match the size and lifting capacity of specific excavator models, ensuring optimal performance and preventing overload issues.

2. Jaw design: The shape, size, and configuration of the gripper's jaws can be tailored to handle specific materials more effectively. For example, wider jaws for bulky items or narrower jaws for precision work.

3. Tooth configuration: The number, shape, and arrangement of teeth can be customized to grip different types of materials more securely. Some applications might require sharp teeth for piercing, while others might need blunt teeth to prevent damage to the handled materials.

4. Hydraulic system modifications: Customizations can be made to the hydraulic system to alter the gripper's opening and closing speed, gripping force, or to add additional functions like rotation.

5. Material selection: Suppliers can use different materials or coatings for various parts of the gripper to enhance durability, reduce wear, or improve performance in specific environments.

6. Additional features: Depending on the application, suppliers might offer add-ons like integrated scales for weighing materials, cameras for improved visibility, or sensors for automated operations.

7. Compatibility enhancements: Custom grippers can be designed to be quickly interchangeable with other attachments, improving versatility on job sites.

It's important to note that the extent of customization options can vary between suppliers. Some may offer minor modifications to existing designs, while others might be capable of creating entirely bespoke solutions. When seeking a custom gripper, it's advisable to discuss your specific needs with several excavator gripper suppliers to find the best match for your requirements.

How to communicate your specific needs to the supplier?

Effective communication with your excavator gripper supplier is crucial to ensure you receive a product that meets your exact needs. Here are some steps to help you articulate your requirements clearly:

1. Define your application: Begin by clearly outlining the specific tasks you need the gripper to perform. Provide details about the materials you'll be handling, the environment you'll be working in, and any unique challenges you face.

2. Specify your excavator model: Provide detailed information about your excavator, including make, model, and specifications. This ensures the gripper will be compatible with your machine.

3. Quantify your requirements: Where possible, provide numerical data. This could include the weight and dimensions of materials to be handled, required grip force, or desired cycle times.

4. Describe your ideal solution: If you have a specific design in mind, communicate this to the supplier. Even rough sketches can be helpful in conveying your ideas.

5. Discuss budget and timeline: Be upfront about your budget constraints and when you need the gripper delivered. This helps the supplier propose realistic solutions.

6. Share your pain points: If you've used standard grippers before, explain what issues you've encountered. This helps the supplier understand what problems need to be solved.

7. Ask questions: Don't hesitate to ask the supplier about their capabilities, previous custom projects, or any concerns you have. This dialogue can lead to valuable insights and solutions.

8. Be open to suggestions: While you may have a specific solution in mind, be open to the supplier's input. Their expertise might lead to innovative solutions you hadn't considered.

9. Request prototypes or simulations: For complex customizations, ask if the supplier can provide 3D models, simulations, or prototypes to help you visualize the final product.

10. Discuss after-sales support: Inquire about maintenance, spare parts availability, and warranty for the custom gripper.

By following these steps, you can ensure that your excavator gripper supplier fully understands your needs, leading to a customized solution that enhances your operations.

In today's competitive construction and excavation landscape, having the right tools can make all the difference. Customized excavator grippers offer a way to optimize your operations, improve efficiency, and tackle unique challenges. Many excavator gripper suppliers recognize this need and offer various levels of customization to meet their clients' specific requirements.

From minor modifications to entirely bespoke designs, the options for customization are diverse. Whether you need a gripper with specialized jaws for handling unique materials, or one designed to withstand extreme environmental conditions, there's likely a supplier who can meet your needs.

The key to successfully obtaining a customized excavator gripper lies in clear communication with your chosen supplier. By thoroughly explaining your requirements, being open to expert suggestions, and engaging in a collaborative process, you can ensure that the final product aligns perfectly with your operational needs.

Excavator Gripper Suppliers

Choosing the right excavator gripper supplier is crucial for obtaining a high-quality, customized solution that meets your specific needs. Tiannuo Machinery, a leading manufacturer in this field, offers exceptional excavator grippers designed to enhance your operational efficiency.

The operation of Tiannuo's grippers is seamlessly integrated with your excavator's hydraulic system, allowing for precise control of clamp movement through pressure oil. These versatile attachments find applications across various industries, including excavation, demolition, ore extraction, and slope cleaning.

To ensure longevity and optimal performance, Tiannuo recommends regular maintenance, including checks on fasteners, proper lubrication, and performance evaluations.

If you're in the market for a reliable excavator gripper supplier, we invite you to explore what Tiannuo has to offer. For more information or to discuss your specific needs, please don't hesitate to reach out to our team:

- Manager: arm@stnd-machinery.com

- Team members: rich@stnd-machinery.com and tn@stnd-machinery.com

Let Tiannuo be your partner in enhancing your excavation capabilities with our top-quality, customizable excavator grippers.

References

- Construction Equipment Guide. (2021). "The Importance of Choosing the Right Excavator Attachments."

- Journal of Construction Engineering and Management. (2020). "Optimization of Excavator Attachments for Improved Efficiency in Construction Projects."

- International Journal of Industrial Ergonomics. (2019). "Ergonomic Considerations in the Design of Excavator Attachments."

- Heavy Equipment Guide. (2022). "Trends in Customization of Construction Equipment Attachments."

- Waste Management & Research. (2018). "Specialized Excavator Attachments in Waste Management: A Case Study."

YOU MAY LIKE

VIEW MOREHigh-vibration hydraulic ballast tamping machine

VIEW MOREHigh-vibration hydraulic ballast tamping machine VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket

VIEW MOREDegree Rotating Hydraulic Tilt Ditching Bucket VIEW MOREExcavator rail clamp

VIEW MOREExcavator rail clamp VIEW MOREExcavators Long Reach Boom

VIEW MOREExcavators Long Reach Boom VIEW MORERailway excavator dustpan bucket

VIEW MORERailway excavator dustpan bucket_1740558626327.webp) VIEW MORERailway track sweeper

VIEW MORERailway track sweeper VIEW MOREExcavator Wood Splitter

VIEW MOREExcavator Wood Splitter VIEW MOREBallast Plow

VIEW MOREBallast Plow