Do China Excavator Standard Arm suppliers test standard arms before shipping?

When it comes to heavy machinery, quality and reliability are paramount. Excavators, in particular, rely heavily on their standard arms for optimal performance and safety. As such, it's crucial to understand the testing processes employed by China excavator standard arm suppliers before shipping their products. This article delves into the rigorous testing procedures these suppliers typically undertake, focusing on three key areas: dimension and shape tolerance detection, material and hardness detection, and performance testing.

Dimension And Shape Tolerance Detection

China excavator standard arm suppliers recognize the critical importance of precise dimensions and shapes in their products. The standard arm is a crucial component of an excavator, and even minor deviations in its dimensions or shape can significantly impact the machine's performance and safety.

To ensure accuracy, suppliers employ advanced measurement techniques and tools. These may include:

- 3D laser scanning: This technology creates a detailed digital model of the arm, allowing for precise comparison with design specifications.

- Coordinate Measuring Machines (CMM): These machines provide highly accurate measurements of the arm's physical geometrical characteristics.

- Optical comparators: Used for inspecting the profile and dimensions of smaller components.

The tolerance detection process typically involves measuring key dimensions such as length, width, and thickness at multiple points along the arm. Suppliers also check for straightness, flatness, and roundness where applicable. Any deviations from the specified tolerances are carefully documented and addressed before the arm is approved for shipping.

Moreover, China excavator standard arm suppliers often use computer-aided design (CAD) software to compare the measured dimensions with the original design specifications. This allows for a comprehensive analysis of the arm's conformity to design standards.

Material And Hardness Detection

The material composition and hardness of excavator standard arms are crucial factors that determine their durability, strength, and overall performance. China excavator standard arm suppliers typically conduct thorough material and hardness tests to ensure their products meet the required specifications.

Material testing often includes:

- Chemical composition analysis: Using techniques such as spectrometry to verify the exact composition of the steel used.

- Microstructure examination: Microscopic analysis of the material's structure to ensure proper heat treatment and absence of defects.

- X-ray or ultrasonic testing: Non-destructive methods to detect any internal flaws or inconsistencies in the material.

Hardness testing is equally important, as it directly relates to the arm's wear resistance and overall lifespan. Suppliers typically use methods such as:

- Brinell hardness test: Suitable for testing large, thick materials.

- Rockwell hardness test: Often used for its simplicity and ability to test a wide range of materials.

- Vickers hardness test: Known for its precision, especially for testing very hard materials.

These tests are usually performed at multiple points on the arm to ensure consistent hardness throughout. Any variations outside the specified range are carefully evaluated and may require additional heat treatment or even rejection of the component.

Performance Test

The final and perhaps most crucial stage of testing conducted by China excavator standard arm suppliers is the performance test. This phase aims to simulate real-world operating conditions and verify that the arm can withstand the stresses and strains it will encounter during actual use.

Performance testing typically includes:

- Load testing: The arm is subjected to various loads, often exceeding its rated capacity, to ensure it can handle peak stresses without deformation or failure.

- Fatigue testing: Cyclic loading is applied to simulate the repeated stress the arm will experience over its lifetime, helping to identify any potential weak points.

- Range of motion testing: Ensures the arm can move smoothly through its entire intended range without interference or excessive wear.

- Hydraulic system integration: Verifies that the arm works seamlessly with the excavator's hydraulic system, with proper pressure and flow rates.

Many China excavator standard arm suppliers use specialized test rigs that can apply precise loads and movements to the arm while monitoring its response. Advanced sensors and data acquisition systems are often employed to collect detailed information on the arm's performance under various conditions.

Additionally, some suppliers conduct field tests, installing the arm on an actual excavator and putting it through a series of real-world tasks. This provides valuable data on the arm's performance in conjunction with other excavator components and under typical operating conditions.

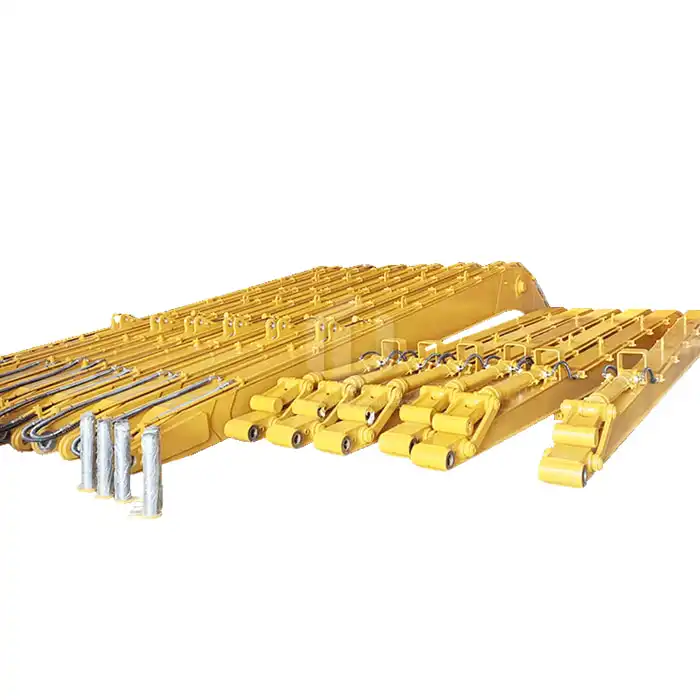

China Excavator Standard Arm Suppliers

The rigorous testing procedures employed by China excavator standard arm suppliers underscore their commitment to quality and reliability. From precise dimension and shape tolerance detection to thorough material and hardness testing, and comprehensive performance evaluation, these suppliers leave no stone unturned in ensuring their products meet the highest standards.

For those seeking top-tier excavator components, Tiannuo Machinery stands out as a premier manufacturer and supplier of standard-size excavator booms and arms. With over a decade of industry experience, Tiannuo Machinery is committed to delivering durable, high-performance solutions that meet and exceed industry standards.

- Material: Constructed from high-strength steel, ensuring superior durability, resistance to wear, and enhanced load-bearing capacity for demanding excavation tasks.

- Maximum reach: Designed for maximum efficiency, with a reach of up to 15 meters, making it ideal for deep excavation, demolition, and long-reach operations.

- Lifting capacity: Engineered to handle heavy-duty applications, supporting loads of up to 30 tons while maintaining stability and operational efficiency.

- Compatible excavator models: Compatible with all major excavator brands, ensuring easy integration and seamless performance across different equipment models.

- Customization: Offering tailored solutions to meet specific project requirements, including customized lengths, reinforcements, and special attachments to enhance operational efficiency.

If you're in the process of selecting a standard size excavator boom and arm manufacturer, we invite you to reach out to our team. Our manager's email is arm@stnd-machinery.com, and our team members can be contacted at rich@stnd-machinery.com and tn@stnd-machinery.com. Let Tiannuo Machinery's expertise and commitment to quality support your excavation needs.

References

- Zhang, L., et al. (2019). "Precision measurement and shape error evaluation of large-scale components." Measurement Science and Technology, 30(8).

- Li, X., et al. (2020). "Material characterization and performance evaluation of excavator boom and arm." Engineering Failure Analysis, 118.

- Wang, J., et al. (2018). "Performance testing and evaluation of hydraulic excavator working devices." Automation in Construction, 93, 1-10.