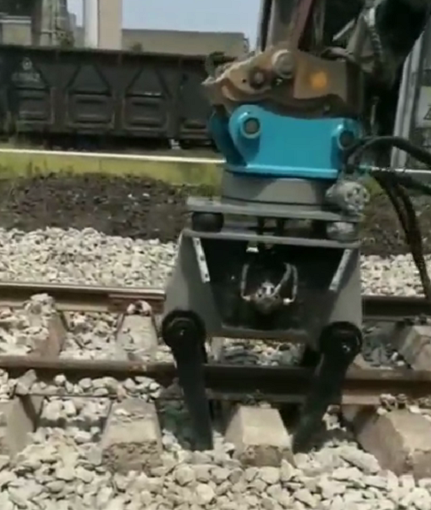

High-vibration hydraulic ballast tamping machine

Function: Tamping ballast after renovation

Tamping Clamping Range: 180-700 mm

Claw Types: Four claws and eight claws available

Suitability: Suitable for various track gauges

- Product Description

About tiannuo machinery

At Tiannuo Machinery, we are committed to delivering top-tier solutions for the railway maintenance industry. With over 10 years of experience, we have become a trusted name in manufacturing and supplying high-quality High-vibration hydraulic ballast tamping machine.

What is a Ballast Tamper?

High-vibration hydraulic ballast tamping machine is a specialized piece of machinery designed to pack (or tamp) the track ballast under railway tracks, enhancing track stability and alignment. This equipment is vital for maintaining the track’s geometry, ensuring safe and efficient railway operations. As railway infrastructure continues to expand, the demand for effective tampers has grown, making them indispensable for railway companies, construction contractors, government agencies, and specialized maintenance firms.

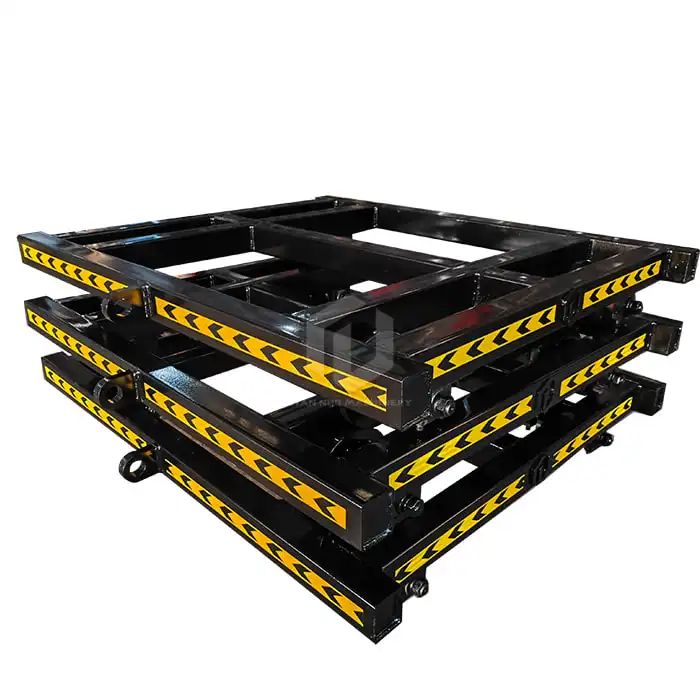

Specification

| Applicable host (ton) | 13 |

| Clamping range (mm) | 180-700 |

| Number of arms held (pcs) | 4 |

| Compaction force (ton) | 10 |

| Work pressure (Mpa) | 18 |

| Length (mm) | 1020 |

| Width (mm) | 1060 |

| Height (mm) | 1750 |

Ballast Tamper Key Features

Precision Tamping: Our Ballast Tamper deliver highly accurate tamping operations, ensuring that track ballast is packed tightly and uniformly to support track stability.

Advanced Automation: Equipped with state-of-the-art automation systems, our tampers reduce manual labor, improve operational efficiency, and provide consistent results.

Durability: Built with high-grade materials to withstand the harsh conditions of railway maintenance, our machines offer long-term reliability with minimal downtime.

Ease of Use: With user-friendly controls and interfaces, our products are designed for easy operation, allowing for quick deployment and effective track maintenance.

Safety Compliance: Adhering to stringent industry safety standards, our tampers ensure the safety of operators while maintaining the integrity of the railway tracks.

How It Works

The High-vibration hydraulic ballast tamping machine operates by lifting the railway tracks slightly and then packing the ballast underneath with precise pressure. This process ensures that the tracks are properly aligned and supported, preventing future shifts that could lead to derailments. The advanced automation features allow for precise control over the tamping process, making sure that each section of the track receives the appropriate level of compaction. Our machines are built to endure the rigorous demands of continuous railway maintenance, providing a reliable solution for maintaining track geometry.

Workshop Display

At Tiannuo Machinery, we take pride in our state-of-the-art workshop where each tamper is carefully engineered. Our facility is equipped with cutting-edge technology, and our team of skilled professionals ensures that every machine meets our high standards of quality. We invite you to visit our workshop and witness the meticulous craftsmanship that goes into producing our industry-leading railway maintenance equipment.

Testimonials

Jane Doe, Chief Engineer, Railway Maintenance Co.

"Tiannuo’s product has transformed our maintenance operations. The machine's precision and durability have significantly improved our track stability, and their customer service is top-notch."

Michael Brown, Infrastructure Director, National Rail Agency

"We have been impressed with the reliability and efficiency of Tiannuo's Ballast Tampers. They have greatly reduced our maintenance times, and the safety features give us confidence in their use across our network."

FAQ

Q1: How often does the product need maintenance?

A1: Regular maintenance is recommended every 500 hours of operation, including checks on hydraulic systems, lubrication, and inspection of wear parts. Tiannuo provides comprehensive maintenance guides and support.

Q2: Can the product be customized?

A2: Yes, we offer customization to meet the specific requirements of your railway maintenance projects. Contact us to discuss your needs.

Q3: What is the delivery time for the product?

A3: Our standard delivery time is 6-8 weeks, depending on the level of customization required.

Contact Us

Ready to optimize your railway maintenance operations with a high-performance High-vibration hydraulic ballast tamping machine? Reach out to us at tiannuo@railwayexcavatorattachments.com or tiannuojixie@railwayexcavatorattachments.com to discuss your needs and receive a personalized quote.